|

|

Diamond Turning

and Precision Machining

|

|

Built on

a foundation of mechanical engineering and machine design experience,

Colorado Precision offers single-point diamond turning and precision

machining services which are unsurpassed. |

|

A

long and continuing relationship with the National Laboratory

system as well as active membership in the American

Society of Precision Engineering assures that CPPI is always at the

forefront of precision engineering and design technology |

|

|

|

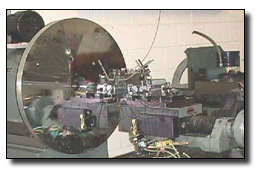

Using a modular

machine tool concept, we assemble diamond turning systems out

of our inventory of high-precision components, maximizing both

flexibility and precision. |

|

When matching

precision machining components (fixtures, drive systems, feedback,

metrology, tables/slides, tooling, etc.) to each specific project's

needs, well-defined limits do not really exist, however, here

are some estimates and historical experiences: |

Size Size |

Currently, we

have the ability to diamond turn a part up to 42" in diameter.

A recently turned part was 36" diameter. Larger parts would

be considered based on the individual project |

Surface Surface |

Heavily dependent

upon part geometry, our diamond turned surface finishes can be

as low as 20Å RMS, as low as 5Å RMS with post-polishing |

Flatness Flatness |

As a general rule

of thumb, our slides are good to 1 microinch per inch of travel.

On a recent 17" square part, the flatness was 1/10 wave

at 633nm over a 4" segment. |

Geometry Geometry |

Our work is generally

in flat and spherical parts. We also have experience building

hyperbolics, parabolics and off-axis ellipses and would like

to discuss parts of any geometry |

home | diamond

turning

| AB

LVDT

| optics | company

info

| facilities/equip. | contact | webmaster

© Copyright

2001 Colorado Precision Products, Inc.

home | diamond

turning

| AB

LVDT

| optics | company

info

| facilities/equip. | contact | webmaster

© Copyright

2001 Colorado Precision Products, Inc. |